To Increase Fuel Mileage in V8 Ford Fox Chassis cars!

www.thatmetalbox.com home

Goal: Get the most MPG reasonably and easily out of the Ford 85-93 5.0. H.O. Windsor engine installed in the Fox Mustang. My angle on this is that I am not looking to increase power, stock numbers are sufficient for my daily driver, a separate car will used for power upgrades. I believe that the overall theme to keep in mind is efficiency; through efficient use of fuel/air resources, power is oftentimes found as a secondary effect...

That being said; I think that there are many ways to improve the stock MPG.

I look at it this way: the pushrod SBF we are concerned with here was first available to buying public about 1963

Lets not forget: The basic electronics we are talking about MAF hail from about 1988, so we are dealing with

**Without a doubt, given modern parts, electronics, methodology, machinery and equipment we can demand more MPG than the factory Setup** but how?

Let us examine the variables that are changeable by the average enthusiast: their own grease-monkey skills, commonly available parts & working with a standard machine shop when needed... without going extreme or expensive.

We all have heard that "THERE IS NO REPLACEMENT FOR DISPLACEMENT" usually folks are talking

about increasing power by an increase of engine size in the form of more Cubic Inches the engine Displaces (CID) or Moves during one

complete cycle of the engine. Picture a syringe, a short and narrow one, a fat and long one. Increasing the displacement of the engine (or syringe) can be done by increasing the

size of each piston diameter (bigger plunger), or the sweep of the piston; the maximum movement up and down (a longer syringe housing holds more). This latter method is called

stroking an engine; many engines including the 5.0 are stroked from the factory. The 5.0 or 302 is a factory

stroked 289 (we will not get into 221 or 260 engines) However all else being equal, increasing the CID will increase the minimum amount of fuel required to run your Small Block Ford pushrod

v8.

all have heard that "THERE IS NO REPLACEMENT FOR DISPLACEMENT" usually folks are talking

about increasing power by an increase of engine size in the form of more Cubic Inches the engine Displaces (CID) or Moves during one

complete cycle of the engine. Picture a syringe, a short and narrow one, a fat and long one. Increasing the displacement of the engine (or syringe) can be done by increasing the

size of each piston diameter (bigger plunger), or the sweep of the piston; the maximum movement up and down (a longer syringe housing holds more). This latter method is called

stroking an engine; many engines including the 5.0 are stroked from the factory. The 5.0 or 302 is a factory

stroked 289 (we will not get into 221 or 260 engines) However all else being equal, increasing the CID will increase the minimum amount of fuel required to run your Small Block Ford pushrod

v8.

While it is true that in general Ford has had smaller Cubic Inch offerings in their V8's when compared to Chevy: 302 versus 350 for example, to

save fuel reducing engine size by way of De-Stroking could be a valid area of experimentation.

”Engines can be modified by being "de-stroked", shortening the stroke to increase maximum rpms and top-end horsepower, at the expense of low-end torque.”

As long as enough power is retained to effectively move the mass in question, reducing the size of an engine could work up to a point.

Why not take the 5.0 H.O. Efi Roller-cam engine back down to 289 CID with factory parts? Worked good enough for Shelby’s gt350 Mustang cars

The 1985-1993 SBF roller blocks: There are a few specifics of these engine blocks that make them a better candidate for Max MPG when compared to other Pushrod SFB:

3) Engine internals [hard parts: non - valvetrain/camshaft]

One can go mad in the quest to reduce friction and reciprocating weight. Some of the racers tricks will apply here; the more weight you have to spin the more power required.

Many of the parts and methods available to professional racers are outside the scope of this document.

Super light pistons, exotic & prepped crankshafts, aluminum or (better for daily driver) titanium connecting rods can all contribute to a light rotating assembly and cost. To buy these parts in the interest of fuel economy would mandate you driving the car for a few lifetimes to recuperate the investment cost of the parts.

Pistons: There are many light and otherwise improved pistons available for the 5.0 at an economical price; in fact there seems to be so many parts available for this engine design that one wonders if it or Chevy 350 - SBC family has the most current aftermarket support.

Piston Material: Three major choices include

Rings:

Ring Material: I believe that it is more important to get the correct size and gap on your rings for your application than a fancy or expensive set(for example forged KBB pistons have high silicon content and therefore expand and contract even more dramatically than OEM forged units, specific gap MUST be set otherwise piston breakage is highly likely) however there is almost no excuse or reason to use Chrome Rings for our MPG build.

http://www.aa1car.com/library/ar293.htm

I. Upper:

I have heard it said that the OEM upper (1987-1993) is good enough for about 300hp and the 1993 cobra upper is good for 350-360. Additionally, reducing the CI of the engine (destroked) will reduce airflow requirements at all rpms making the OEM upper a good choice. The Max MPG engine will not have a massive operating range, achieving maximum torque at lower engine rpms. A model for efficient design is an infinitely variable transmission, the idea is that you would build an engine to max power and efficiency at a specific rpm, always run that engine at that specified RPM and vary the mechanical advantage to achieve differing output. All modern locomotives run with this methodology, excepting that their engines are powering electric motors. Small vehicles have successfully followed this model but the variable trans design cannot as of yet withstand moderate power output much less our torquey 5.0! Suffice it to say that either will suffice for max MPG, with the std upper getting some props as shown:

below post wythors from url http://forums.corral.net/forums/showthread.php?t=1030224

contains a graph showing STOCK INTAKE compared to 1993 COBRA INTAKE, graph shows stock upper at an advantage for HP and torque production (in basically stock engine) until 3500 rpm:

Later, Bullitt95 responds to the information represented in the chart saying;

"Just proves that on a mild 5.0, even the Cobra intake is too much and causes a loss of torque below 3500rpm. A Tmoss ported stock

intake would be better on a stock-headed, stock cammed 5.0 until it's time to upgrade those items. With better-flowing heads, the Cobra intake (Tmoss ported of course )

would then be a great mod."

It stands to reason, then, that the stock upper intake could be used for max MPG effort, especially when reducing CI as in a 5.0 destroked to 289

When considering any system there is always a limiting factor, this is the piece that first reduces the potential of that system. For example we can consider a city water system. A holding tank is 40 feet in the air and flows through 4” pipe. Lets say that it branches to a 2” pipe running to your house and you happen to have a 1” hose you are filling your pool with… however your water meter is 0.5” thus becoming the limiting factor of the system, even though you could replace the house pipes with 3” it would not be as effective as replacing that one limiting factor. This is why I believe that it is worth it to replace the stock lower intake with this below piece but am satisfied with the stock upper. Below text from HOLLEY catalogue, duplicated here:

http://www.sacramento-mustang.com/cc/cc_holley300505.htm

“Holley engineers discovered that the lower intake manifold was one component whose

design would be most restrictive to maximum air flow. A new lower manifold was designed with larger runners and smoother contours to take full advantage of the higher air flow potential brought

on by the camshaft”. The camshaft packaged with this kit is similar to the E303 FRPP cam but has significantly taller lobes.

“Holley engineers discovered that the lower intake manifold was one component whose

design would be most restrictive to maximum air flow. A new lower manifold was designed with larger runners and smoother contours to take full advantage of the higher air flow potential brought

on by the camshaft”. The camshaft packaged with this kit is similar to the E303 FRPP cam but has significantly taller lobes.

In the course of looking for the proper camshaft more variables will come into play than in any other one engine part. For example I know that my engine will have less cubic inches of displacement than a stock 5.0. and want to favor MPG.

To get the right direction, I concluded a few observations I have realized that big block engines use larger camshafts than their smaller brethren, and keep the same “general attitude” meaning road manners, drivability is the same, this is true with a stroker engine also. I have infer then, that to destroke an engine and keep the same cam the engine will “seem” to have a more rowdy camshaft or “have more cam”, more "camie". also know that if you stroke an engine to a larger displacement using a larger cams Therefore I have decided that the approximate direction I should take would be to 1) less duration than stock because of less cubes. 2)less overlap than stock because of intended lower rpm expected 3)quicker ramp speeds, take advantage of better valve springs & modern design.

|

PART |

INT .050 |

EXH .050 |

INT LIFT |

EXH LIFT |

ADV INT |

ADV EXH |

LSA |

OVERLAP |

|

1986 STOCK |

|

|

0.444 |

0.444 |

266 |

266 |

116 |

36 |

|

1989 STOCK |

|

|

0.444 |

0.444 |

276 |

266 |

116 |

39 |

|

1993 COBRA |

|

|

0.479 |

0.479 |

270 |

270 |

116 |

33.9 |

|

ISKY 371252 |

204 |

210 |

0.465 |

0.48 |

252 |

257 |

112 |

30.5 |

|

ISKY 371257 |

210 |

218 |

0.48 |

0.5 |

257 |

265 |

112 |

37 |

Obviously one would expect - and

be correct - that most aftermarket heads to be designed for performance and excellent breathing, providing some massive flow numbers at peak valve opening. The Max MPG engine will not

benefit from this. Remember the overall goals is efficiency, we want to keep the ports relatively small and the air/fuel velocity high at low engine speeds (sit at traffic lights much?) Not

many heads will fit these criteria, only a few come to mind

Obviously one would expect - and

be correct - that most aftermarket heads to be designed for performance and excellent breathing, providing some massive flow numbers at peak valve opening. The Max MPG engine will not

benefit from this. Remember the overall goals is efficiency, we want to keep the ports relatively small and the air/fuel velocity high at low engine speeds (sit at traffic lights much?) Not

many heads will fit these criteria, only a few come to mind

1) Factory E7TA truck heads used on 1987-1993 Mustang V8

2) Factory E6AE fast burn high swirl 1986 only

3) Factory GT40P Explorer cylinder heads

4) Dart Iron Eagle

Read this article to become exposed to the concept of “restrictive design” Cam Truth by Buddy Rawls

http://www.wighat.com/fcr3/camtruth.htm

…High Port Velocity = Excellent Low RPM Performance

Small restrictive inlet ports provide high port velocity. Small restrictive inlet ports also require lower rpm levels to achieve maximum torque output. The requirement is for the engine to produce ample cylinder pressure for the desired performance level and RPM range…

I read: if you use stock heads and build for torque you will not have to spin the motor to high rpm, in fact it wouldn’t belong at high rpm’s.

How does this really help the Max MPG engine?

If you have gobs of torque you can change your gearing, you can turn a very taller gear at speed. You need plenty of torque for the engine to maintain power at higher speeds as friction will continue to increase the faster you go. Wind resistance and tire resistance to the road continue to increase. Look to section V. for information regarding gear ratio selection with MPG in mind.

9, 28, 50 ounces?

The SBF pushrod Windsor came with 28 inbalance and then adopted the 351W’s 50 ounce. You can neutrally balance your engine (0 ounce imbalance), a costly endeavor using expensive Mallory metal

Really good resource on many topics:

http://www.grapeaperacing.com/GrapeApeRacing/tech/dampers.pdf

Get a good harmonic balancer. Strange as it may seem, this usually means a heavier one; when compared to the various units available for the application, the heavier units do the job better.

http://www.team3s.com/FAQudp.htm

A crank is a long, rigid metal shape; if you tap with a hammer it "rings" (especially forged cranks; cast cranks have some internal dampening). So what? Well, a hammer hitting it is only ONE way to cause the crank to RESONATE and exhibit harmonic VIBRATIONS. Another way is to RUN the engine! The engine is a vibration factory (as we all know)...and if left undamped, crank harmonics can build up at certain (harmonic) rpms and these vibrations DON'T just disappear, they have to be DISSIPATED! The best way to dissipate them is via the SPECIFICALLY-DESIGNED-TO-DO-THIS "Harmonic Dampener" hanging off the front of the crank. It has an elastomeric (rubber) isolator between the hub and the HEAVY outer ring, and is as a unit, designed to damp harmonics at the critical frequencies seen by the crank.

The heavier the outer ring, the better it damps, and the higher its efficiency at damping. NASCAR LONGtrack engines use HEAVY dampeners, to allow the bearings to live the long race length; the shorter the race, the more often the bearings get changed (after EVERY RACE), the LIGHTER a dampener can be used because lighter is a little faster to accelerate the engine due to lower rotational inertia. You are trading bearing/crank life for speed. Where do YOU want to go on this? Are you lucky?

The OTHER way to damp harmonic energy (which MUST GO SOMEWHERE) is through the main bearings, into the main bearing saddles on the BLOCK. This can cause premature wear/fatigue/flaking of main bearings, and cracks in the main bearing saddles on the block. This is a poor tradeoff for "an underdrive pulley".

Does this ALWAYS happen? No. Some people may not push their cars very hard very often; some may not do longtrack racing; some may not keep their cars long enough to discover the bearing wear, or to crack anything; the underlying design may be robust enough to cover over this MISTAKE in parts selection. There is a pretty big industry in harmonic dampeners, different TECHNIQUES for dampening (Fluidampr, ATI, BHJ, "The Rattler", etc) but they ALL DAMPEN HARMONICS because it is important...

...As a person who comes to the hobby from an enginebuilder's standpoint (not sales/driver/etc) this misinformation about "you don't need a dampener" or when that fails "our unorthodox pulley does the same thing" is sad. It gets down to this. Do ya feel lucky? ... This is an insult to your engine's health. It MAY take it in stride; but it is an offense. I respect my hardworking engine too much to burden it with the sometimes insane levels of harmonics that can occur without harmonic dampener protection. Where else are you going to cut corners? What other basic engine building good practices is one going to spit on, and which will be the straw that breaks the camel's back...eventually?

...NHRA rules require an SFI-approved harmonic balancer for cars going into the 11's. With all the IDRA etc drag groups out there using NHRA tracks, better to be legal BEFORE someone challenges it/you and disqualifies you...".

--- Jack Tertadian

http://www.team3s.com/FAQudp.htm

Ford used two firing orders in the SBF Windsor engine. The 289 and early 302 shared one while 351 W always had another order that the 5.0 H.O. ended up adopting.

What follows is heresy straight from random www; not known if wrong or right - take it as such.

“The 302 ho firing order is supposed to produce less harmonics than the standard 302 order ..

...The crank and cam in combination determine firing order. You can make certain changes in firing order by making the change on the cam, but it has to agree with the crank. Basically you have two pistons come to tdc at same time. The cam can determine which one is on exhaust/intake and which one is on compression/ power. There are only certain changes in firing order the cam can make without having to alter crank.”

I understood from Ford engineers, back in the day. That they changed to the 351W firing order to ease the load on the front main bearing.

As far as I know, the staggered firing order is better for the overall efficiency of the engine... The 1-5-4-2-6-3-7-8 fires too many cylinders that are adjacent relative to the 1-3-7-2-6-5-4-8 order... resulting in better balance.

Here's my opinion anyway. I say yes, there is an advantage. It will be a very small one, though. I'd guess something like a 1% increase in power. That can be hard to see on a dyno as you could have 1% variation run to run with no changes. The 351W firing order is supposed to better for crankshaft and bearing life, but if you have a fairly mild motor those parts aren't going to be stressed anyway.

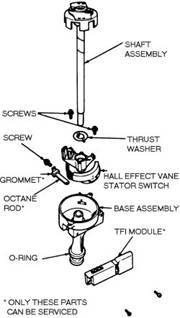

Stock electronics are quite good even though the TFI distributor was a modification/upgrade

to the previous Hall Effect dizzy which was an modification/upgrade to the old 1960’s – 70’s points distributor body. Clean up a stock unit and check for excessive play,

that’s all you should have to do, however if you must: MSD Ignition

part number 8456 drop in replacement, superior in all ways. At $290.10 it has few real benefits to the realize the goal in the scope of this document

Stock electronics are quite good even though the TFI distributor was a modification/upgrade

to the previous Hall Effect dizzy which was an modification/upgrade to the old 1960’s – 70’s points distributor body. Clean up a stock unit and check for excessive play,

that’s all you should have to do, however if you must: MSD Ignition

part number 8456 drop in replacement, superior in all ways. At $290.10 it has few real benefits to the realize the goal in the scope of this document

Thick Film Ignition (TFI) modules were used on Ford vehicles with distributors from the early 1980s to the mid-1990s. It was used on a number of Ford's engines, the EFI 5.0 engines in particular. The TFI module is a gray box fitted to the side of the distributor. It is about one inch wide, and about four inches long. The distributor itself uses a Hall Effect sensor.

The TFI modules are available as Holley 891-105 or Accel 35368 (~$46), as well as from a number of aftermarket sources.

Of course if you are serious about MPG or racing you should get a good upgraded computer system (total replacement) such as Comp Cams’ FAST, XFI Fuel Injection Systems or a piggyback add-on management system for the EEC IV items such as the Anderson Ford Motorsport's PMS; programmable engine management system

Or STKR, LLC's TwEECer to name two popular units. At the least get a tune! My plan is to do all I can myself, and then get a tune, after which - if I am not satisfied I will invest in some sort of systems add-on but have not researched this direction yet.

Restrictive exhaust is no good. The stock 5.0 H.O. dual exhaust system with h-pipe and tubular headers is good enough for Max MPG, but there is no reason to not upgrade. I would suggest equal length shorty headers and replacement mandrel bent h or x pipe 2.5” with single cats from BBK or the like. As far as I can determine there is no real penalty to opening up the exhaust system even 3” pipes should be fine as long as full exhaust is retained, and A PROPER TUNE IS COMPLETED.

The venerable Ford 9” (Nine Inch rear) is tough to beat, tough to break and the

Mopar and Chevy guys use them all the time. However, for MPG purposes its not too good, instead we will actually borrow from Chevy in a way; the 8.8 and 7.5 rear housings are C-Clip type

axles which Chevy had been using in all their muscle cars, the 10 bolt 12 bolt 14 bolt are all C-Clip rear ends, hey I don’t like them for performance, they are not what you call

“positive axle retention” rears, this means that if there is a break anywhere from the wheel all the way in to the center where the c-clip attaches to the axle, your wheel can

fly off and away. Yeah so my other FOX has a nine inch but it’s a fact that the 8.8 is more efficient, some sources

say 3% more efficient than the 9” because of how the ring and pinion mesh. There is simply more contact between the two on a 9” for a much stronger union, creating more drag

in the form of friction.

The venerable Ford 9” (Nine Inch rear) is tough to beat, tough to break and the

Mopar and Chevy guys use them all the time. However, for MPG purposes its not too good, instead we will actually borrow from Chevy in a way; the 8.8 and 7.5 rear housings are C-Clip type

axles which Chevy had been using in all their muscle cars, the 10 bolt 12 bolt 14 bolt are all C-Clip rear ends, hey I don’t like them for performance, they are not what you call

“positive axle retention” rears, this means that if there is a break anywhere from the wheel all the way in to the center where the c-clip attaches to the axle, your wheel can

fly off and away. Yeah so my other FOX has a nine inch but it’s a fact that the 8.8 is more efficient, some sources

say 3% more efficient than the 9” because of how the ring and pinion mesh. There is simply more contact between the two on a 9” for a much stronger union, creating more drag

in the form of friction.

Most rear axles are described by their ring-gear diameters, with larger being stronger and heavier. A Ford 9-inch has a ring-gear diameter of, you guessed it, 9 inches closely followed by the GM 12-bolt at 8.875, with the Mustang 8.8 rear at 8.80 inches. Lets not forget little brother 7.5” (ring gear at 7.50 inches) axle...

Most Ford owners look down upon the 7.5" rear but it is a fairly tough unit. People have used them in 12-second cars without problems, and they're not nearly as weak as people make them out to be. If you're thinking about upgrading your 7.5" economically, you shouldn't have any reservations so long as you're not drag-racing heavily. The 7.5" rear is about 40-80 lbs. lighter than a comparable 8.8" rear. Keep in mind that while you can indeed swap in a locking center section on the 7.5" rear, it's tough to find one.

http://www.coolcats.net/tech/general/axleinfo.html

There are a few extreme ways to go. Because their internals are lighter and therefore more efficient - you could go for the 7.5 with an open differential to net best MPG for least money, nobody cares about them you could get them for free, or you could built it or the 8.8 in an insane fashion, similar to a high dollar race unit, you can get gun drilled axles, lightened gear sets, etc - but it would not really be cost effective. I recommend getting a 8.8 freshened up to stock specs, get a good set of highway gears, and keep the drums because they don’t drag at all when not in use while I understand that discs do so - albeit slightly, creating drag/friction but it’s cheap to keep those drums. The other positive side of using the 8.8 is that I am not against more power, it oftentimes comes as a secondary result of making an efficient system, and It is much stronger than the 7.5. Additionally all of the 8.8 rears have the quad shock brackets, while only early 7.5’s have them. The 8.8 rears usually have the trac-lok limited slip differential (no its not a posi that’s GM trademark for limited slip) which does not help MPG but I like to have! Lastly along with the previous point, you have to like this car if you are really trying to get MPG you will be most likely totally or partially rebuilding your rear axle because for one thing you must choose a highway friendly gear ratio, and that costs to set up (ha! It costs each time you do so, unless you have a 9” rear axle!) so don’t spend a bunch of money on a 7.5!

Also, the parking brake spring on a Mustang is designed for automatic adjustment at the ratchet handle end, but it means the cable is always in a slight tug-of-war condition and the shoes will drag. Not much, mind you, but every little bit counts. I added an additional spring on each cable, concentric with the originals, to provide positive release. It seems to vibrate itself to that point within 50 miles or so, which means after a long trip, the brake handle will come up an extra couple of notches (as it tries to self re-adjust.) Pull it up a second time and it's normal again. Not that it matters, since it's actually functional at either adjustment height.

http://www.floridahappiness.info/Mustang/efficiency.htm

If you have gobs of torque you can change your gearing, you can turn a very taller gear at speed. You need plenty of torque for the engine to maintain power at higher speeds as friction will continue to increase the faster you go. Wind resistance and tire resistance to the road continue to increase. Look to section V. for information regarding gear ratio selection with MPG in mind.

On the other hand, if you are not doing 100% freeway miles, such as stop and go traffic commute you wont want to extreme gear your car, as read:

http://forums.stangnet.com/showthread.php?p=7342235

stangnet.com

How to save gas in a 5.0 thread

ninety15.0 Official Member -

Gear ratio: Honestly the stock 2.73 are horrible for economy. They are simply too long. 3.27 and 3.55 are the best ratios for getting good mileage...and which of those you choose depends on the conditions you drive in. All highway -- 3.27. Mixed driving -- 3.55. Gears give you higher torque multiplication...and that effective increase in torque gets the vehicle moving easier (less throttle input) and gets you into high gear sooner. Both my brother and i got better mixed driving mileage after swapping to 3.55's and 3.73's from the stockers. Our highway mileage has remained exactly the same.

Driving style: Get a vacuum gauge and watch it like a hawk. Manifold Vacuum is directly proportional to the efficiency of a motor. The less throttle input required to maintain a desired speed..obviously the better. An engine is simply an air pump...when you let more air in...you let more fuel in. Also...do not listen to people who tell you to shift really early ~below 2000. While this is good advice some of the time it is not entirely true. Buy a Vac gauge and shift real early and you will see what i mean. The motor loads up really bad when you accelerate in the lower rpms. I bring 1st and 2nd up to at least 2500 every time and b/c you arent pressing the gas hardly at all...vacuum is high and you arent using very much gas. And when you upshift you dont land really low in the rpms...so the subsequent gears require less throttle input to accelerate as well.

You can wring out quite a bit of economy from these cars if you are willing to keep your foot out of it.

NKau Founding Member -

Unless you are commuting at 75+ on the freeway often, 2.73's are going to be more detrimental to fuel mileage than say a 3.27-3.73 gear.

|

Factory Ford 8.8 Axle Gear Ratios (Available with Traction-Lok) |

|

|

2.73:1 |

In the trunk of my 1991 white mustang coupe auto |

|

3.08:1 |

(dont have any more Now 3.0:1) These were stock in my silver 1991 notch (I swapped the entire 8.8 into my 1987 CHP SSP to sell) |

|

3.27:1 |

These were in the 1987 CHP sedan, both axles were junk, I cut the quad brackets off for my 9" rear (now has 3.0:1 even gears installed, 3.89:1 available) I installed in the silver 1991 notch that got wrecked I still have the gears |

|

3.55:1 |

These are in the 1987 Tbird turbocoupe 4 cylinder turbo thunderbird I am hauling into my backyard |

|

4.11:1 |

Aftermarket - Currently installed in 1991 white mustang notchback auto less than 400 miles on these in rebuilt trac-loc |

(1.) Body Style:

There are your choices, I have heard it said that the rear design of the hatch interfaces with the air stream in a more efficient way when at speed but I do not have any data, nor do I know what to believe. The sedan body style is lighter, the 4 cylinder with stripped options no ac no power windows) is the lightest mustang ever made. This would lead me to believe that Daily Driving if traffic, many stops, or stop and go on your commute for instance, the coupe makes the most sense. If long haul on the highway then perhaps the hatch. Forget the convertible

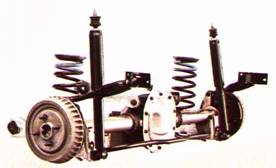

The Fox-body Mustang based on the Fairmont intermediate-sized platform was introduced with MacPherson-struts in front and a live rear axle. Although larger than the Mustang II it weighed less. Ford offered two performance options—a 302 2bbl and a turbocharged 2.3L four cylinder.

http://home.pon.net/hunnicutt/history_79_93.htm

The Ford Fox platform; a lightweight and relatively simple unibody automobile architecture that Ford used for 26 years. Initial appearance was the the Ford Fairmont and Mercury Zephyr appearing in 1978. Ford Fairmont, Mercury Zephyr, Ford Mustang, Mercury Capri, Ford Thunderbird, Mercury Cougar, Ford Granada, Lincoln Continental, Ford LTD, Mercury Marquis, and Lincoln Mark VII all used the Fox Chassis design sometimes called fox body or foxbody.

These cars were slick for their time. The first mustangs to have encapsulated front nose

Lower the car, decrease wind resistance,

Add vortex generators on as used on semi trucks, Airtab.com sells them for cars and trucks

Underdrive pulleys & upgraded alternator, IMO should be done together. This will reduce some parasitic loss, without discharging your battery at idle. If you drive in very hot whether like me or folks in NV, AZ perhaps change all but water pump pulley, keep that one at the stock smaller diameter (when compared to the aftermarket) and it will not slow down the water pump as much as it would if you installed both the smaller crank pulley AND larger water pump pulley

Get the FMS aluminum drive shaft. Its lighter and a reciprocating part of the

drivetrain so there is a gain to be had by lightening this part FMS-M-4602-G Ford

Racing Driveshaft Assemblies $249.95 Diameter (in) 3.500 in. 1330 U-joint Driveshaft, 1330 U-Joint, Aluminum, One Piece, Ford, Mustang, Each Driveshaft Style

One-piece Length (in) 45.500 in. 28 spline yoke. For 1979-1993 and 1994-2004 mustangs COBRA, GTS, GT, LX, GHIA, L, COBRA SVT Axle Model Ford 7.5 in., Ford 8.8 in.

Get the FMS aluminum drive shaft. Its lighter and a reciprocating part of the

drivetrain so there is a gain to be had by lightening this part FMS-M-4602-G Ford

Racing Driveshaft Assemblies $249.95 Diameter (in) 3.500 in. 1330 U-joint Driveshaft, 1330 U-Joint, Aluminum, One Piece, Ford, Mustang, Each Driveshaft Style

One-piece Length (in) 45.500 in. 28 spline yoke. For 1979-1993 and 1994-2004 mustangs COBRA, GTS, GT, LX, GHIA, L, COBRA SVT Axle Model Ford 7.5 in., Ford 8.8 in.

Maximize timing I read 12 adv best for these purposes

Always tune, tune is not just for WOT, after all hard parts are in get your tune.

Lastly, wheels and tires;

Lastly, wheels and tires;

Lets face it, car people are usually vain about their

cars, and a HUGE part of the overall LOOK of a car stems from wheel/tire combo

That being said, the lighter the tire/wheel combo the better for MPG

Think of it in extremes; let’s say that you stood next to a giant flywheel, one for a huge old steam powered Iron Mountain Cornish mine pump for example… this wheel is 40 feet in diameter & weighs 160 tons! It is rotating at 10 RPM. There is another wheel next to you on a table it is 20 inches tall, at 10 RPM; it is your personal physical job to KEEP them at that speed. It is obvious that starting the large flywheel takes more energy; the extreme example shows It takes more energy for the larger wheel to

1) start and accelerate

2) keep it moving

3) stop it

People arguer that the larger wheel is easier to keep moving because of its inertia, but its larger mass against gravity proclaims this is not so.

Minimize inertia and rolling resistance, this means light wheels and tires with less contact patch... if choice between two similar tires you want less rubber actually touching the road so choose accordingly.

If a choice between two tires and one has softer compound go for the harder compound, within range of acceptable pressures recommended, go for the higher pressure in the range and balance all tires (there is a racers tire filler that connects to two tires at once, thereby equalizing pressure when filling Percy's High Performance Tire Pressure Equalizers: Part Number: PHP-01003 $29.95

Wheels have quite a large effect on how a car acts; how handles and stops, also its efficiency.

For purposes of Max Mpg, You should look to the lightest wheel/tire combo within reason; considering size and cost. You must have a combo who’s contact patch allows sufficient grip to the road for BRAKING as well as handling (think of trying to steer or brake with bicycle sized tires on the front of your ‘stang).

The 4 cylinder wheel and tire combo are not desired by most anybody and can be had cheaply, however the V8 front disc brakes from 198x and newer will prove to be to large for the front wheels. Another factory option that is possible (I do not know if they are road legal) are the aluminum spare wheel found in some of the mustangs.

These wheels clear the larger later fox V8 brakes. I suppose you could go 4 cylinder wheels in the back and the spare wheel with a good modern tire on the fronts. What I mean to communicate though, is don’t get expensive and heavy large diameter BLING RIMS, they will not help you save money and gas.

http://forums.corral.net/forums/showthread.php?t=1025705

Used Parts Sources:

1989 5.0 H.O. used short block

1967 289 standard used short block

New Borg-Warner (Now Tremec) T5 Z series

1987 8.8 rear axle from SHP SSP; 3.27:1 gears track lok

1987 8.8 rear axle from Thunderbird TurboCoupe 3:50 gears track lok rear disc relocated quad shock brackets

1987 tcoupe also supplied pedal brake and clutch assembly for use with manual hydraulic clutch, also supplied master & slave clutch cylinder.

1984 – 1988 Ford F150, F250, E150, E250 E4TA Bellhousing (shown here) for use

with hydraulic cylinder and Ford SBF pushrod engine block with 6 bolt pattern. Will NOT work with toploader OR T5 without CUSTOM Machining to create an adaptor bracket

(shown here) for use

with hydraulic cylinder and Ford SBF pushrod engine block with 6 bolt pattern. Will NOT work with toploader OR T5 without CUSTOM Machining to create an adaptor bracket

1991 8.8 rear axle came with my white notch mustang AOD with 2.xx gears car also came with 4.11, also supplying fuel rails and stock upper intake.

New Parts

Crane Cams roller camshaft

Holley Systemax I lower intake

Pro.. Harmonic Balancer

164 tooth flywheel

11” clutch

Combo that came together with these parts

1989 block with its stock forged pistons & new rings

5.155” connecting rods from 1967 fastback engine

2.87” crankshaft from 1967 fastback engine, 28 oz imbalance

16” OEM Aluminum Pony Wheels

Lower the car with drop spindles in front and adjustable rear lower control arms in back.